Semiconductor photolithography, also known as semiconductor lithography or simply "lithography," is a crucial process in the manufacturing of integrated circuits (ICs) and other semiconductor devices. It involves creating intricate patterns on silicon wafers or other substrates to define the electrical and physical structures of the semiconductor components.

In the realm of semiconductor technology, miniaturization is the driving force, leading to smaller and more advanced electronic devices. Photolithography plays a fundamental role in this miniaturization process by enabling the fabrication of increasingly smaller components on a semiconductor wafer. It allows for the precise transfer of photomasks, which are masks with intricate patterns, onto the surface of a wafer through a series of steps.

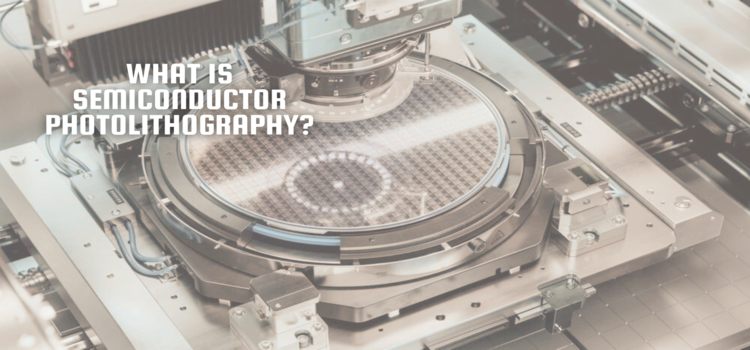

The photolithography process typically begins with the selection of a substrate, usually a silicon wafer, and a protective layer called the photoresist. The photoresist is a light-sensitive material that is coated onto the wafer's surface. Next, a photomask, which is essentially a stencil carrying the desired pattern, is aligned accurately above the wafer. The photomask contains clear areas (where light passes through) and opaque areas (where light is blocked).

Once the photomask is correctly aligned, the semiconductor photolithography process moves to the exposure step. In this step, a light source, often ultraviolet (UV) light, is directed through the photomask, transferring the pattern onto the photoresist-coated wafer. As the light passes through the clear areas of the mask, it causes a chemical reaction within the photoresist, altering its properties. The opaque areas of the photomask prevent light from reaching the corresponding areas of the wafer, leaving the photoresist unaffected.

After exposure, the wafer undergoes a process known as development. This involves removing the unexposed areas of the photoresist while leaving behind the patterned regions. Different types of development techniques, such as solvent-based or aqueous-based solutions, are employed depending on the type of photoresist used.

Following development, additional semiconductor fabrication steps are performed, such as etching, deposition, and ion implantation, utilizing the patterned photoresist as a guide. These subsequent steps help to refine the features of the semiconductor device and create the desired electrical circuitry. Ultimately, the completed semiconductor device will consist of various interconnected components, such as transistors, capacitors, and interconnects, which form the basis of integrated circuits.